Four stroke Engine Development

By RD Chinoy

Introduction:

Our engine development has so far been limited to two stroke engines. And i have been using Neels Excellent Dat2t for all my development work for the past few years. I feel enough builds have been done across India. To show that if developed well a two stroke engine can not only have its power output bumped up but you can have good engine reliability also. Some of our builds which have done over 150 Kmph on the speed gun have gone on to last for over 35,000 Kms with not so much as a ring change. Your avrage rebuild life is aprox 10,000 Kms. With most engines not even lasting 2000 Kms.

I have also used Ian Williams Mota Engine simulator in the past. But moved over to Neels software because it has a more complex Ignition model. We also found that the sim output from Neels s/w was matching the Dyno output perfectly. Well Neels s/w outputs power at the crank. We where finding our Dyno runs done for rear wheel power where identical down to 50 RPM.

Having proved what can be done with the right approach to tuning on the two strokes we thought it would be nice to do the same for four strokes. So this is my first commercial build. For a customer. I am thankful to the customer (Mohit) for not only funding the development but for allowing me to keep his car. The plan for the car is to develop the engine over a series of stages or steps. A breif is given below.

· Port the head.

· Install a good street performance cam

· Shave the head

· Build proper headers not loud Exhausts.

· Install a custom cold air intake system.

· Replace the NB O2 sensor with a WB unit and output a simulated NB O2 output to the stock ECU

· Install a custom Digital ECU with WB and Knock support.

· Install a Turbo Charger.

While I wont go so far as to say such software programs will one day kill the Dyno. They are for sure a valuable tool to have in any tuners bag of tricks. They allow you to cut down on Dyno Development time. And allow people without access to a dyno a way to design and develop engines that will perform.

The Engine:

The Engine is a Maruti Baleno

Engine. It is a long stroke motor. The company claims 94 BHP at the crank.

(Update): A Stock Baleno Makes under

60 BHP at the hub on the RR Dyno.

The Development

Process:

What I like about both Dat4t and Dat2t the two simulators Neels has developed is the ability to brake your engine up into modules. This saves you a lot of time. For example you can define templates for a Mikuni 28mm Flat slide, or a Mikuni 28mm round slide, 4 petal reed cages, 6 petal reed cages etc. And then just include them in your project. Without having to re-enter all the data. It also makes it very easy to see how swapping parts around will effect the power output.

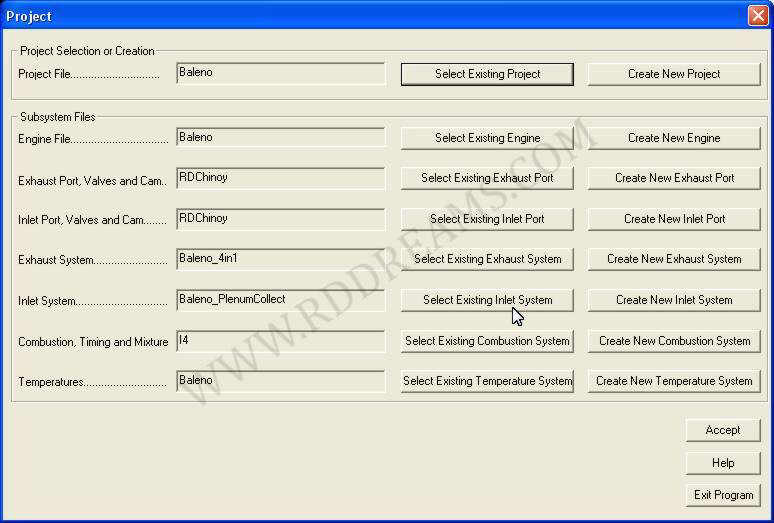

The first step in the Development process is then to define your project on the first screen of Dat4t shown below.

The Project editor.

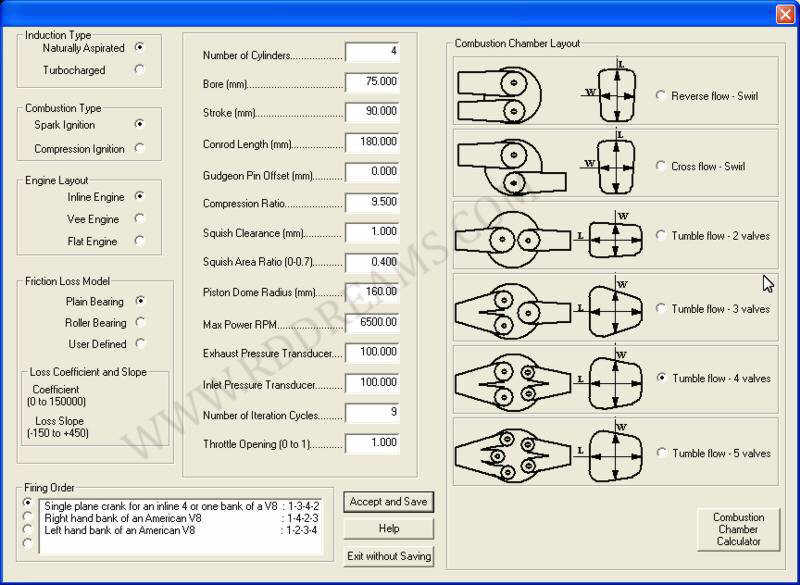

The next screen allows you to edit each of the project components starting with the engine. Here you define your engine and type of Valve system used. Most of the entries are pretty simple to understand. And the help file is quite extensive.

The Engine File:

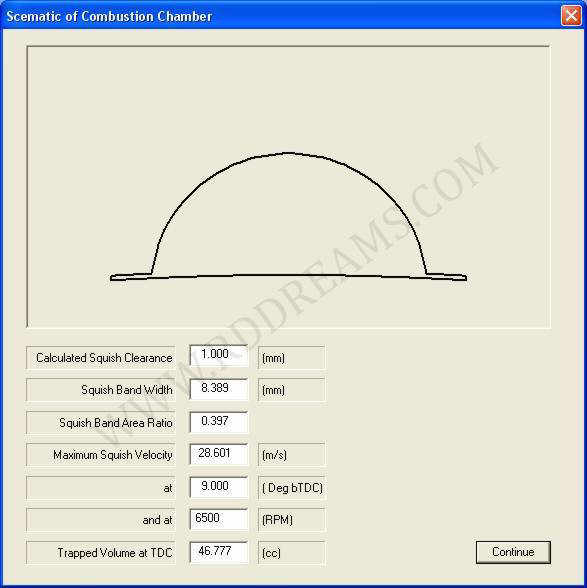

The Head (Volume based on target CR)

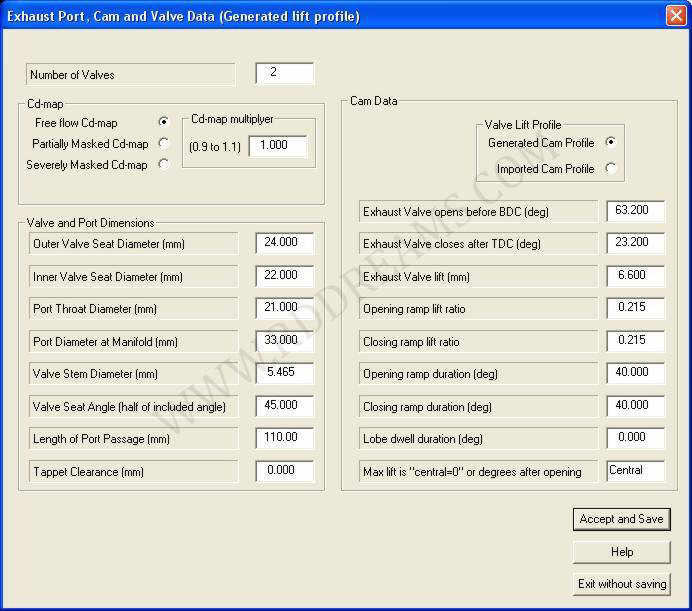

The Exhaust Port Cam and Valves

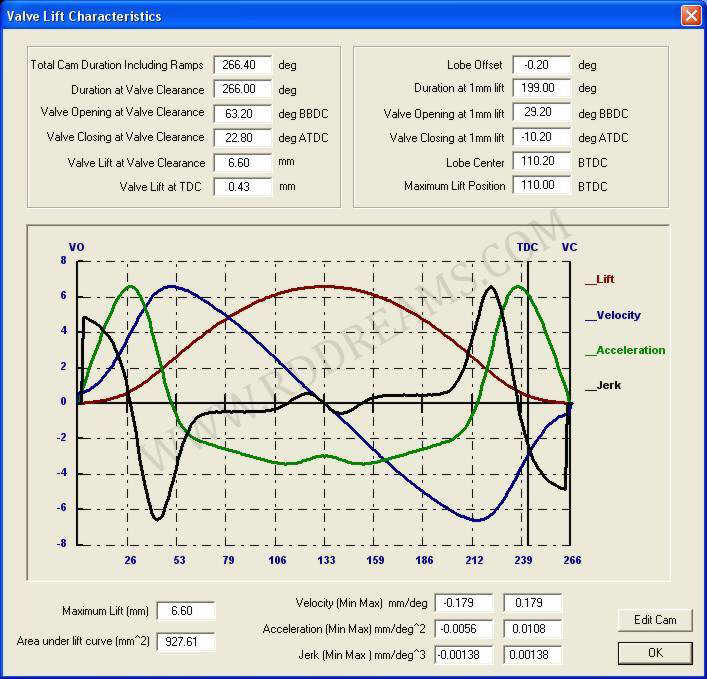

Exhaust Cam Profile

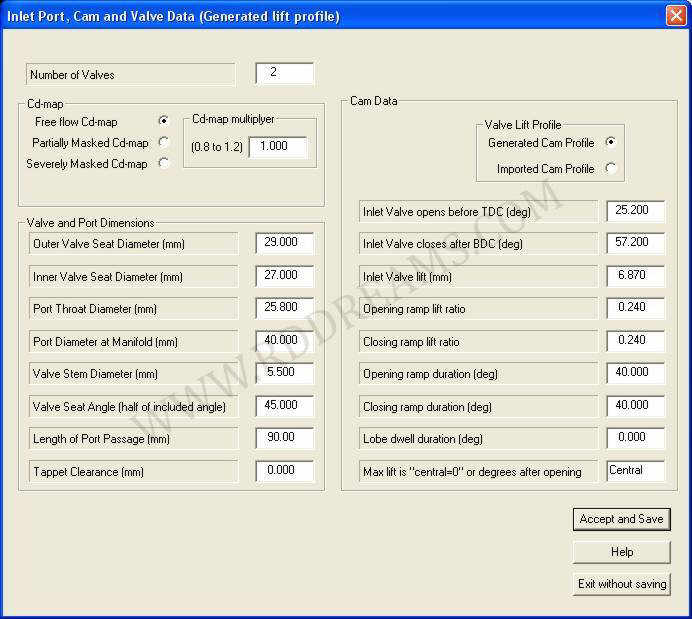

Inlet port, cam and valve data.

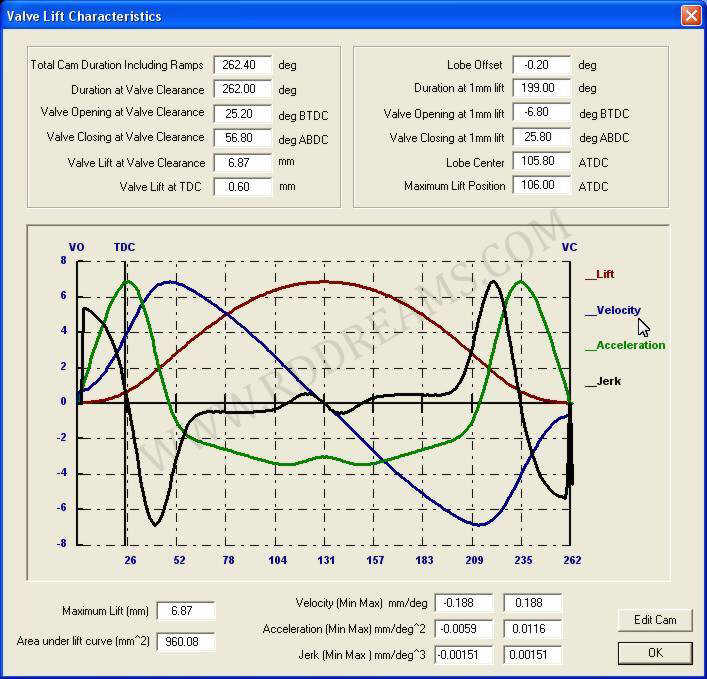

The Inlet Cam Profile.

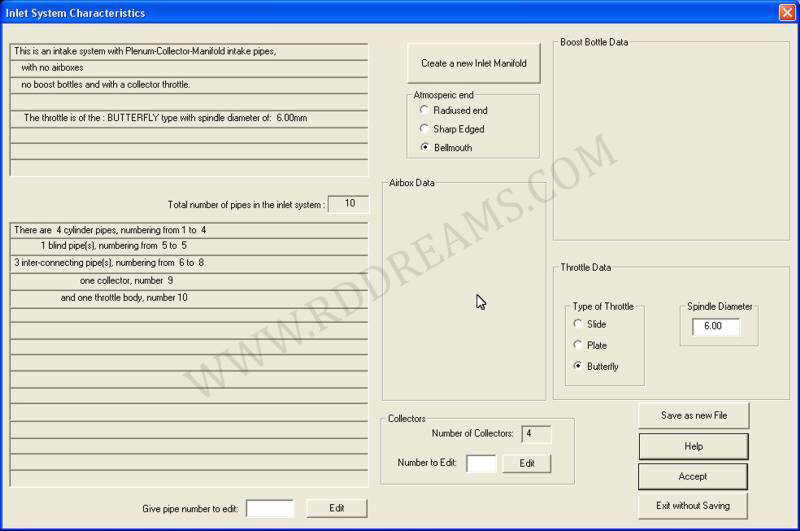

The Intake Manifold

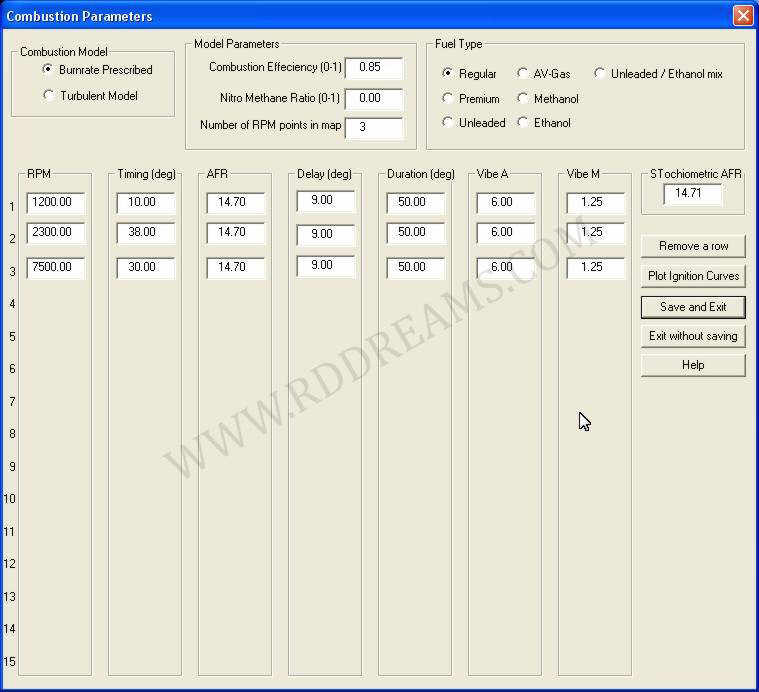

Combustion Model and Info.

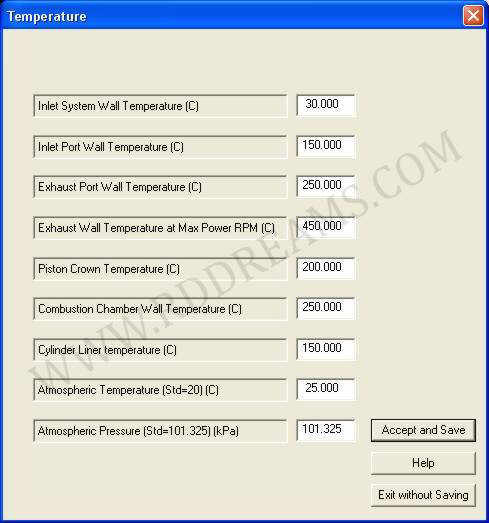

Engine Temps

This concludes all the data that needs to be entered up for the simulator to work. At first it may seem daunting but very soon you can have this data entered up really fast.

The next step is to run the actual simulation. This is done with a separate program called EngMod4t.exe when you run this you are shown a list of all the engines and projects defined to date. You select your project file in this case Baleno and let the simulator run. The simulator allows you to define a start RPM, a End RPM and a RPM step. For our example we have used a start RPM off 2500 a finish RPM off 7500 with an RPM step off 500. As we zero in on our header lengths the RPM step can be dropped to 100 or even 50 RPM. But be warned that such small RPM steps can take a few hours to simulate.

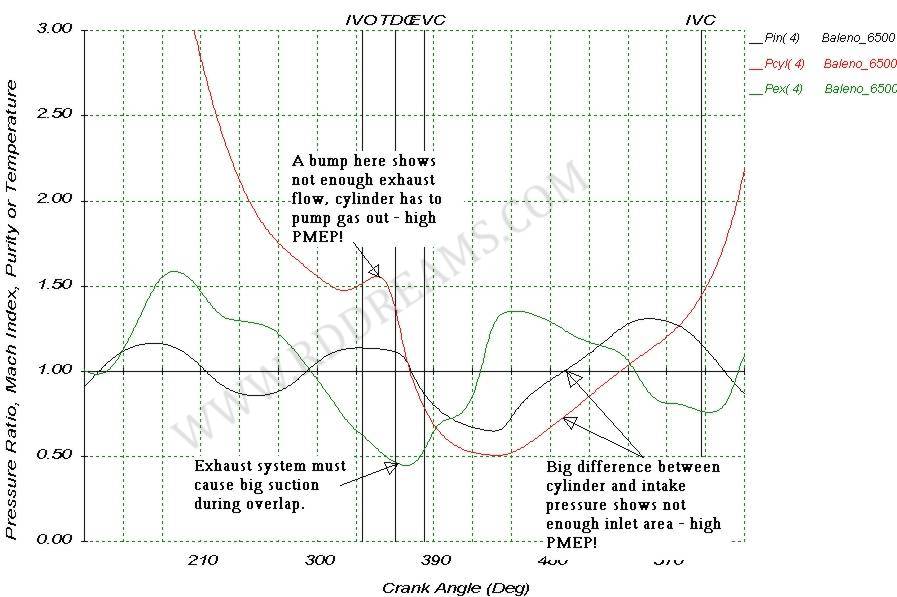

While the simulation is being done you have the option to watch the pressure traces. This in a cool feature to have because it lets you see when the pipe start to work and for how long. You can opt to view either the intake pressure traces for Intake Manifold design or the Exhaust pressure traces for Exhaust design. You can chose to view a single cylinder or all four cylinder.

Here is a small Flash animation showing you what the pressure traces look

like.

Note: In case you missed the Animation just click on the > Play button above

to re-play it as many times as you like.

Here is a small drawing explaining how to use the info in the pressure traces and what your trying to achieve while building a header.

The Results:

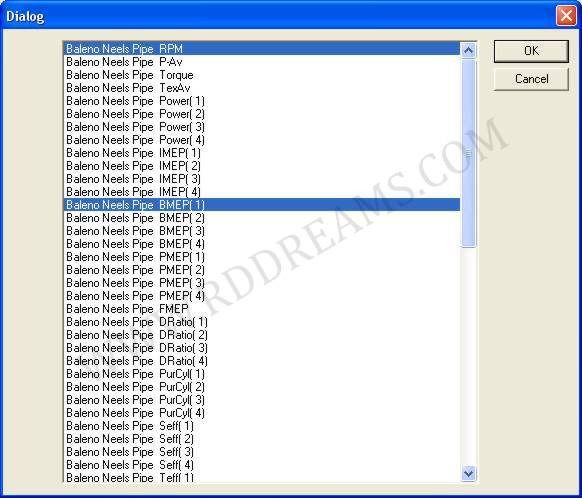

Once the simulation is done. You are shown a power output graph for your engine. To access presure traces for each RPM step as well as many other details you need to use the 3rd and last software component of this package which is Post4t. This is the post processor viewer.

Here are just some of the Engine parameters you can view or plot on your screen.

The Post4t Viewer.

Final Dyno Curve showing BHP vs

RPM

(Red Line shows Exhaust Designed by Neels Black shows

my Design)

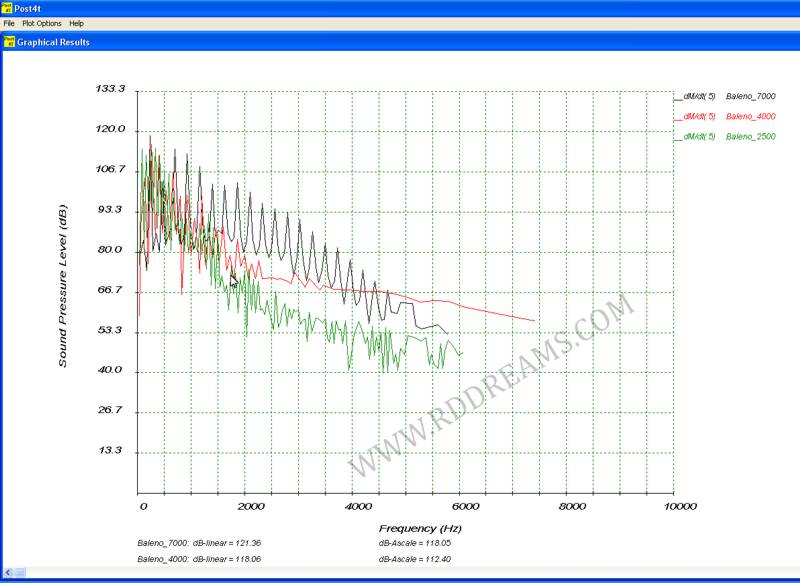

There are hundreds of engine parameters that you can view thru the post processor. And explaining them is beyond the scope of this document. The help file included with the post processor is a good place to read and understand all the info available to you after a run. Below is another interesting example of the kind of data available. It shows you the Noise level and Frequency output of your Exhaust. This can help you in designing quiet Exhausts either for street or track. And is a valuable tool in meeting noise restrictions as imposed by most racing bodies today.

This Exhaust Produces 121 DB @ 7000 RPM measured at 1 Meter behind the

Exhaust.

We hope you have enjoyed this insight into Engine Development using Neels Engine simulator.

Dr. Neels Vanik can be contacted by e-mail. vannik@mweb.co.za

If I can help answer any questions you may have on

using a licensed copy of his software please feel free to post up on www.rddreams.com